R&D

Research and Development- Well qualified R&D professionals with specialization in Food Technology, Process Engineering, and Design & Instrumentation

- 300 days of product development trials in a year

- Continuous research on agriculture product based food

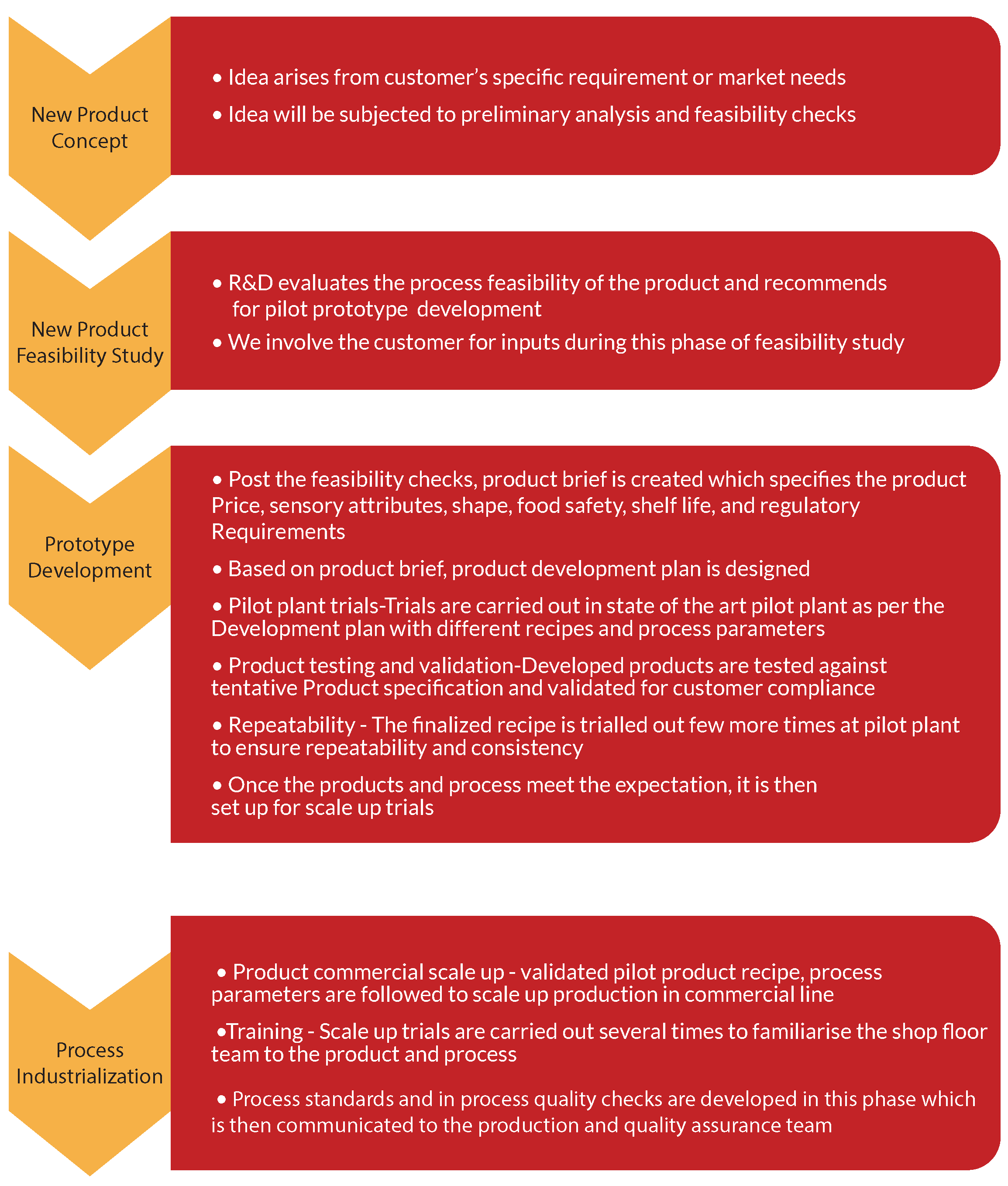

For successful product development projects, we adhere to the below steps from Conceptualization to Commercialization...

Step 1: New Product Concept

- Idea arises from Customer's specific requirement or market needs

- Idea will be subjected to preliminary analysis and feasibility checks

- R&D evaluates the process feasibilit of the product and recommends for pilot prototype development

- We involve the customer for inputs during this phase of feasibility study

- Post the feasibility checks, product breif is created which specifies the product price, sensory attributes, shape, food safety, shelf life, and regulatory requirements

- Based on product breif, product development plan is designed

- Pilot Plant trials- Trials are carried out in state of the art pilot plant as per the development plan with different recipes and process parameters

- Product testing and Validation- Developed products are tested against tentative product speficiation and validated for customer compliance

- Repeatability - The finalized recipe is trialed out few more times at pilot plan to ensure repeatability and consistency

- Once the products and process meet the expectation, it is then set up for scale up trails

- Product Commercial scale up - Validated pilot product recipe, process parameters are followed to scale up production in commercial line

- Training- Scale up trials are carried out several times to familiarise the shop floor team to the product and process

- Process standards and in process quality checks are developed in this phase which is then communicated to the production and quality assurance team